عميل هندي يطلب آلة صنع مسحوق الإطارات لدينا لإطلاق عمل جديد في مسحوق المطاط

We recently delivered a set of tyre powder making machine to an Indian customer who plans to produce rubber powder. Aimed at producing 20-mesh rubber powder with a 4-ton/hour output, this project showcases our ability to provide customized tyre recycling solutions for clients entering new industries.

Recently, we successfully delivered a set of tyre powder making machine to a customer in India, including a tyre shredder and a rubber cracker mill. This customer’s company primarily operates in the warehousing and transportation support industry. However, they are now expanding into the rubber powder production sector, taking an important step toward sustainable resource reuse.

Customer Requirements

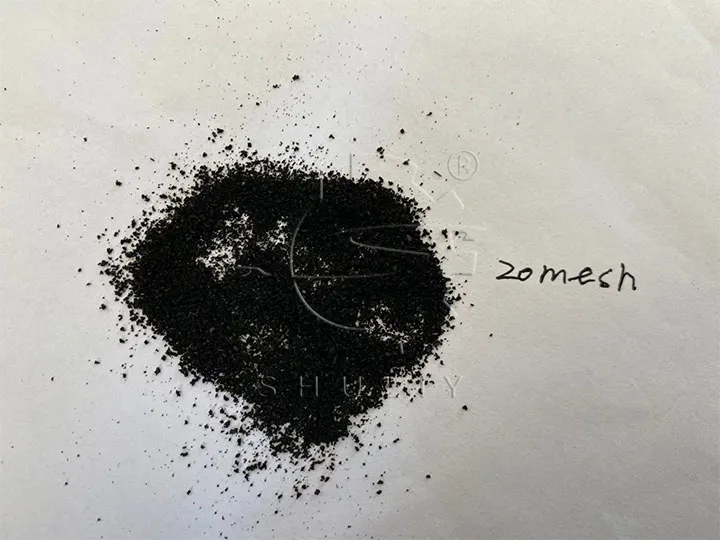

The customer aimed to produce 20-mesh rubber granule from waste tyres, with a target output of 4 tons per hour. During initial discussions, they emphasized the importance of equipment stability, ease of maintenance, and a well-matched production line layout.

Our Recommended Solution

Our sales manager Tina carefully assessed the customer’s goals and working conditions, and recommended a tailored tyre powder making machine configuration that met their needs:

- Tyre Shredder: For pre-cutting whole tyres into manageable rubber strips or chunks, preparing them for fine processing.

- Rubber Cracker Mill: To further crush shredded rubber into fine powder (up to 20 mesh), forming a solid basis for further screening or refinement.

This setup balances capacity and stability and is easy to operate—ideal for new entrants to rubber powder production.

Technical Parameters of Tyre Powder Making Machine

| عنصر | المواصفات |

| Rubber Tyre Shredder Machine | Model 1600 Heavey type shredder capacity: 10 tons/h Crushing size: 70-150mm Conveyor belt size: 1200*3000mm Rubber belt thickness: 10mm Hopper size: 4500*2000mm Voltage: 440v 50hz 3p |

| مطحنة مسحوق المطاط | Model : 660 rubber crusher output: 20mm capacity: 4tons/h Color Customization |

Project Progress & Tyre Powder Making Machine Delivery

The customer approved the proposed configuration and confirmed the order. We completed the manufacturing and assembly on schedule, followed by successful pre-shipment testing. The rubber granules making machine has now been safely delivered to the customer’s site in India, and installation and trial runs will proceed shortly under their arrangements.

Why Choose Us As Your Tire Recycling Machine Supplier?

This project highlights not only our technical expertise in إعادة تدوير الإطارات but also our experience in helping non-manufacturing businesses build their first production lines. Whether you are starting fresh or upgrading an existing setup, we provide customized equipment and layout planning to fit your exact production and budget needs.

If you’re planning to enter the rubber powder or granule industry, feel free to contact us for a reliable and cost-effective solution tailored to your operation.