10 Key Questions to Ask Your Supplier Before Buying Waste Tire Recycling Machine

Before investing in waste tire recycling machine, asking the right questions can save you time, money, and potential future headaches. In this guide, Shuliy Tyre Recycling Machinery Company shares 10 key questions that every buyer should ask when selecting equipment to ensure that it meets production needs, complies with local standards, and delivers long-term value.

When investing in a waste tire recycling project, choosing the right waste tire recycling machine is critical. Different raw materials, capacity requirements, and end product types will affect the model and price of the equipment you choose. If the wrong equipment is purchased, it can lead to higher investment risks, insufficient production capacity, or high operating costs.

As an experienced tire recycling machine supplier, Shuliy Tire Recycling Machinery has summarized 10 key questions you must ask your supplier before purchasing, helping you make the right decision.

1. What Types of Raw Materials Can the Machine Process?

Different markets have different waste tire types—whole tires, tire blocks, bead wire sections, or tread rubber. You need to confirm whether the waste tire recycling machine or production line can handle your common raw materials, including truck tires, OTR tires, and bicycle tires.

2. What is the Capacity Range of the Equipment?

Capacity (500kg/h, 1t/h, 3t/h, etc.) determines your project scale and payback period. Always ask for the actual output instead of theoretical numbers to correctly evaluate production efficiency.

The output of our rubber powder machine depends on the fineness of the rubber powder you require — the finer the powder, the lower the output will be.

3. What Is the Size And Quality of the End Product?

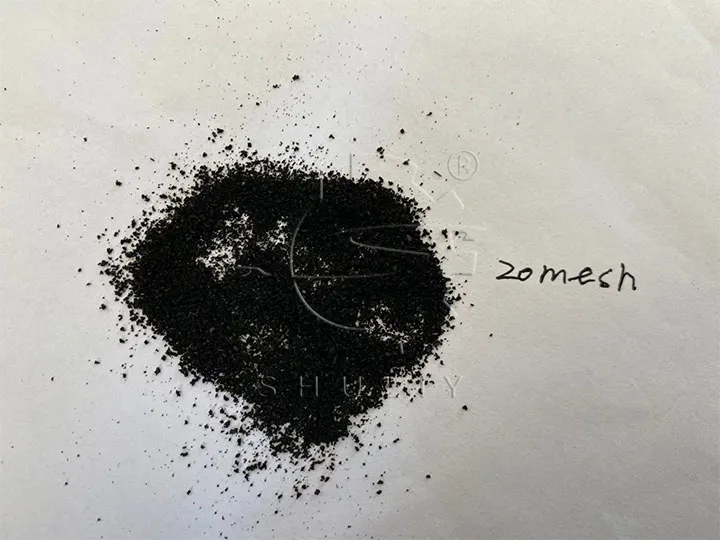

Will you be producing rubber granules or rubber powder? What particle size do you require (e.g., 0–5mm, 10–30mm)? Is the purity sufficient to meet your market demand? Confirm these details with the supplier before purchasing.

Our rubber cracker mill includes screening and magnetic separation processes, ensuring a final rubber powder purity of up to 99%.

4. Is It A Single Machine or A Complete Production Line?

Some customers only need a tire cutter machine, while others require a complete rubber powder production line (cutting – steel wire separation – shredding – rubber powder production). Confirm whether the supplier can provide a one-stop solution.

5. What Is the Energy Consumption And Operating Cost?

Electricity consumption, blade replacement frequency, and labor costs all affect your operating expenses. Ask your supplier for the power consumption and daily maintenance costs of the waste tire recycling machine.

6. Can The Machine Be Customized According to Factory Layout?

Does your factory layout suit standard equipment? A professional tire recycling plant supplier can customize production line layout, feeding, and discharge systems to help you maximize space utilization.

7. What Is The Material And Lifespan of The Blades And Wear Parts?

The material (alloy steel, hardened steel, etc.) and durability of blades directly affect production stability. Ask whether the supplier provides long-term spare parts supply and how often blades need replacement.

8. Do You Provide Installation And Training?

Once the waste tire recycling machine arrives, does the supplier offer on-site installation and operation training? This is especially important for new investors, as it helps speed up the start of production.

9. What Is The Warranty Period and After-sales Service?

Warranty terms, response speed, and spare parts availability are crucial for stable production. Choose a manufacturer that offers fast after-sales support and reliable spare parts supply.

10. Is The Equipment Compatible With Your Country’s Standards And Requirements?

Before purchasing, check whether the waste tire recycling machine meets your country’s electrical standards (voltage, frequency, plug type), environmental regulations, and climate conditions. Some regions require specific dust control systems, noise reduction, or corrosion protection. A professional supplier can adjust the design to ensure smooth installation and compliance with local laws.

Why Choose Shuliy Waste Tire Recycling Machinery?

As a professional waste tire recycling machine manufacturer, we provide a complete range of waste tire recycling equipment, including tire shredders, tire cutters, tire debeaders, rubber powder machines, and steel wire separators.

- Single machine or complete line supply

- Customization based on factory layout

- Installation, commissioning, and training services

- Fast after-sales service and long-term spare parts supply

If you are looking for a reliable waste tire recycling machine supplier, feel free to contact us for detailed equipment solutions and quotations.