How Rubber Powder Machine Ensure Output and Powder Quality

Our rubber powder machine is designed to deliver stable output and high-quality rubber powder. With wear-resistant components, integrated screening and magnetic separation systems, and reliable after-sales support, it ensures consistent production and up to 99% powder purity, helping customers achieve efficient and profitable tire recycling.

In tire recycling, the rubber powder machine is a critical machine for processing waste tires into fine rubber powder. As a professional tire recycling equipment supplier, we focus not only on production capacity but also on the consistency of the powder quality. This ensures that our customers achieve reliable results in their recycling operations.

Optimized Structure and Material Design

Our rubber cracker mill uses wear-resistant alloy blades and a reinforced roller structure, ensuring stable performance even under heavy workloads. A well-designed transmission and cooling system allows the equipment to run for long periods while maintaining consistent output.

Integrated Screening and Classification System

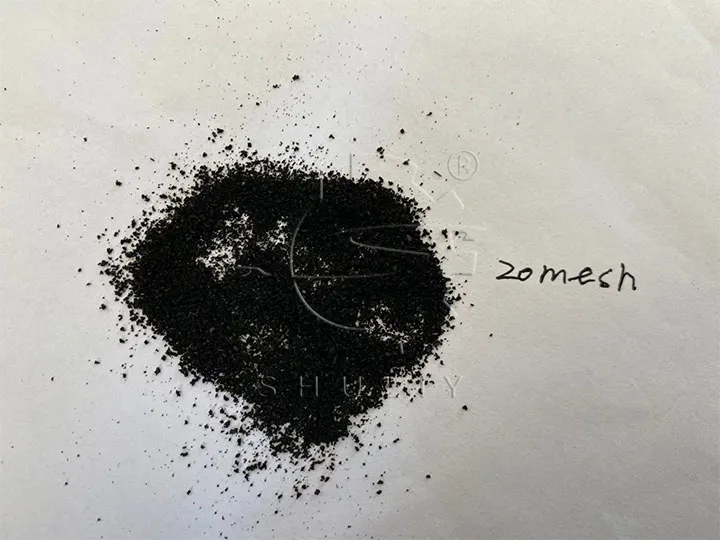

To ensure uniform particle size, the rubber powder machine is equipped with a multi-layer screening system. Larger rubber particles are automatically recirculated for regrinding until they reach the required fineness. This process helps customers obtain rubber powder that meets market standards.

Magnetic Separation and Impurity Control

Scrap tires often contain steel wire and other impurities. Our rubber crusher machine is equipped with a magnetic separation system that efficiently removes metal contaminants during production. This enables the final rubber powder to reach up to 99% purity, improving product quality and reducing equipment wear.

Balancing Output and Fineness

We provide rubber powder machine in different specifications according to customer requirements, and we remind customers that there is a direct relationship between powder fineness and output. The finer the powder, the lower the output will be. By offering tailored production solutions, we help customers strike the right balance between market demand and production capacity.

Operation Guidance and After-Sales Support

Beyond the machine itself, we provide installation, operation training, and maintenance guidance. Proper operation and timely maintenance further ensure stable performance, extend service life, and continuously deliver rubber powder that meets requirements.

Rubber Crusher Machine Price

The price of a rubber powder machine is closely related to its capacity, configuration, and the required powder fineness. As mentioned earlier, finer rubber powder requires more grinding steps, which may reduce output and influence the overall investment. Our rubber crusher machines are equipped with wear-resistant materials, advanced screening systems, and magnetic separation devices to ensure stable production and high-quality powder. While the initial price may vary depending on the model and customization, customers benefit from long-term efficiency, reduced maintenance costs, and higher product value, making it a cost-effective choice for tire recycling projects.