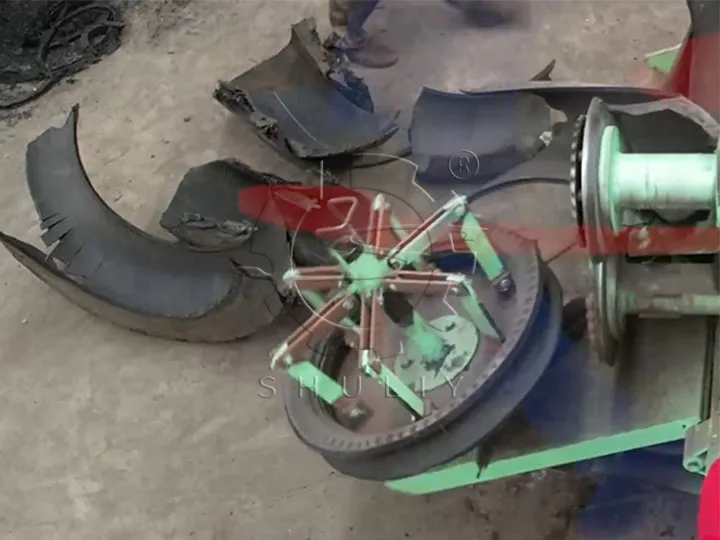

Tire Bead Removal and Cutter Machine

The tire bead removal and cutter machine is designed to process 900–1200mm steel-belted waste tires, removing bead wires and cutting tires in one step. With a capacity of around 3 tons per hour, it’s an efficient solution for truck tire pretreatment.

How the Tire Dismantling Machine Works

- Place the tire vertically on the worktable and align it with the cutting position.

- Activate the hydraulic system to securely clamp the tire in place.

- Two circular blades cut along the bead area.

- As the sidewall beads are removed, the tire is simultaneously cut into sections.

Working Video

Benefits of Using This Tire Bead Removal and Cutter Machine

- Protect downstream shredder blades: Tire bead wire is very hard. Removing it first significantly reduces shredder blade wear, downtime, and maintenance costs.

- Increase overall line throughput: With pre-processing, shredding runs more smoothly, so your line handles more tires per hour.

- Monetize bead wire: Separated bead wire can be easily baled and sold, creating extra revenue.

- Clean cutting and thorough separation: The tire is clamped and positioned before cutting/pulling, so bead wire and rubber are separated more completely and downstream shredding is easier.

- Simple operation, low labor: One operator can complete loading, cutting, unloading, and collecting; training is straightforward.

- Durable blades: Optional high wear‑resistant blade materials; blades support regrinding and replacement to lower long‑term spare parts costs.

Application of Tire Bead Removal and Cutter Machine

The bead removal and cutting machine is commonly used in the pretreatment stage of fully automatic rubber powder production lines.

When paired with a steel wire separator, it first removes the tire bead wires and cuts the tire, allowing the material to proceed to the crushing and grinding stages. This process effectively improves rubber purity and reduces wear on downstream equipment.

Complete Tire Recycling Line

For higher capacity and lower total cost, we recommend placing this machine in a complete tire pre‑processing and recycling line. A typical flow is:

- Bead removal and cutter machine: First removes and cuts the tire bead, separating bead wire and rubber rings to reduce load on downstream equipment.

- Tire steel wire separator: Further processes the cut bead rings to thoroughly separate steel wire from rubber, making the wire easy to bale and sell and the rubber ready for reuse.

- Tyre shredding machine: Shreds the de‑beaded tires in one or two stages; discharge is more uniform and energy consumption is lower.

- Rubber powder machine: Further refines shredded rubber into granules or powder for use in recycled materials, modified asphalt, floor mats, and other applications.

Parameters of The Tire Sidewall Remover and Cutter Machine

Here are some basic specifications of the machine. Feel free to contact us for more details, including pricing, photos, and videos. We can also provide you with a complete tire recycling solution.

| Item | Specification |

| Applicable Tire Size | 900mm – 1200mm |

| Function | Bead wire removal + Tire cutting |

| Max Output Capacity | Up to 3 tons/hour |

| Main Motor Power | 7.5+3 kW |

| Cutting Blade Material | Cr12MoV |

Qatar Customer Application Case

In Qatar, we serve a tire recycling customer focused on tire pre‑processing. To boost line efficiency and protect their shredder, they purchased and commissioned this tire bead removal and cutter machine. On site, the equipment processes about 40 tires per hour (actual throughput varies with tire size and operating rhythm). The customer reports that de‑beaded tires feed into the shredder more smoothly with fewer maintenance stops, and the separated bead wire can be baled and sold for additional income.

Get a quote and complete solution support

If you are planning tire pre‑processing or a full tire recycling line, leave us an inquiry. We can match the right equipment model to your needs (passenger/truck/OTR tire), size range, target capacity, site and power conditions, or provide a complete line solution and layout—from bead removal and separation to shredding and rubber powder.

To help us respond quickly, please include: