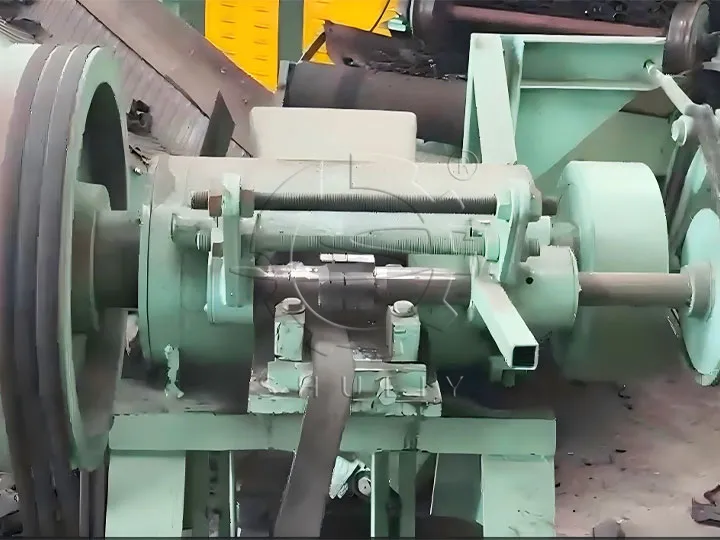

Waste Tire Block Cutter

The waste tire block cutter is one of the core machines in a waste tire recycling line. It is mainly used to cut rubber strips, processed by the tire strip cutter, into uniform rubber blocks, making them easier to handle in the next steps, such as shredding or grinding.

Role of The Tire Block Cutting Machine

This machine is typically used as the third step in a semi-automatic rubber powder production line. Working together with the tire ring cutter and strip cutter, it cuts rubber strips into blocks approximately 3–5 cm in size. These rubber blocks are easier to store, transport, and process in the following crushing stages.

This video shows a tyre block cutter efficiently cutting rubber strips into uniform blocks ready for subsequent crushing or grinding processes.

Why Should You Invest in a Tyre Block Cutter?

Drastically Increase Grinder Efficiency and Output

Feeding uniformly sized tire blocks into the rubber powder machine, rather than whole tires, prevents system clogs and ensures stable operation at peak performance. This ultimately boosts your rubber powder output by up to 30%.

Significantly Reduce Rubber Crusher Maintenance Costs

A rubber powder mill’s cutters and screens are expensive wear parts. Pre-treating tires with a waste tire block cutter drastically reduces the wear on these core components, more than doubling their lifespan and significantly lowering your maintenance costs.

Lower Your Energy Consumption

Pre-cutting tires into smaller blocks significantly reduces the grinder’s workload. This effectively saves on energy costs by lowering the electricity consumed for every ton of rubber powder you produce.

Features of The Waste Tire Block Cutter

- High-Strength Blades: The blades are made of high-quality alloy steel, offering excellent hardness and wear resistance. They are durable and can be re-sharpened and reused multiple times.

- Efficient Cutting: The cutter delivers even and precise cutting, ensuring uniform block size for stable downstream processing.

- Strong Shearing Force: Designed with powerful shearing capability, it can handle rubber strips of various thicknesses with ease.

Parameters of The Tire Block Cutter

The technical parameters listed below are for reference purposes only. For more detailed and expert information, please leave us a message on our website, and we will respond to you as soon as possible.

| Type | QKJ-358 Common Tire Block Cutter | Updated Tire Block Cutter |

| Item | Technical parameter | Technical parameter |

| Motor power | 5.5 KW | 18.5kw |

| Rubber block size | 3*5*6cm | 5cm*5cm |

| Capacity | 800kg/h | 1500kg/h |

| L*W*H | 1.0*0.8*1.4m | 1.3*1.1*1.5m |

| Weight | 800kg | 1200kg |

Frequently Asked Questions (FAQ) of The Waste Tire Block Cutter

Q: What Is The Maintenance Schedule Like for This Machine?

A: Daily maintenance is minimal, mainly involving lubrication and inspection. The primary maintenance task is blade sharpening, with the frequency depending on usage.

Q: What Is the Difference Between Using This Block Cutter and A Tire Shredder?

A: Compared to a tire shredding machine, the waste tire block cutter is a more cost-effective initial investment. It excels at creating uniform blocks with lower energy consumption, making it the ideal pre-treatment choice for semi-automatic rubber powder production lines.

Q: Do You Supply Spare Parts, Especially the Blades?

A: Yes, we maintain a full inventory of spare parts, including blades, for all our models.

Get Your Custom Solution for Rubber Powder Production

The waste tire block cutter is your first step toward a more profitable recycling business. Let our experts help you configure the perfect pre-treatment solution to match your capacity needs and budget.

Contact us today for a free quote, along with more details, pictures, and videos of the machine.