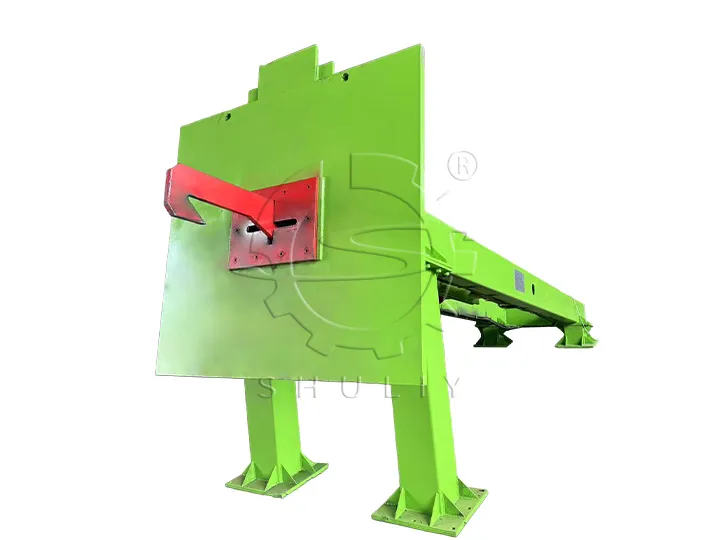

OTR Debeader

The OTR debeader is a wire pre-processing machine designed for the treatment of OTR tires, mainly for the direct extraction of steel wires from the bead of tires with diameters between 1800mm and 4000mm.

Main Functions and Applications

The OTR debeader is primarily used to pull out the thick, hard steel wire from the bead of an OTR tire in one piece. The steel wire in the bead of an engineering tire is so strong and deeply embedded that if it is not pre-treated and goes directly into the tire recycling shredder, it will cause rapid wear and tear or even damage to the knives.

By separating the steel wire first, it not only improves the service life of the equipment, but also lays the foundation for subsequent cutting, shredding and sorting.

Features & Advantages of The OTR Tire Debeader

Our heavy-duty OTR tire debeader is built for strength, durability, and consistent performance.

- High pulling force hydraulic system for extracting ultra-strong OTR steel beads

- Reinforced gripping hook designed for large and heavy tires

- Adjustable structure suitable for different OTR diameters (25–63 inches)

- Safer operation with hydraulic lock and remote/start control

- Thickened machine base for handling extremely heavy tires

- Stable output & low maintenance for industrial recycling plants

These features make our OTR tyre debeader suitable for continuous, heavy-duty operation in demanding environments.

How Does The OTR Debeader Work?

The operator will place the large tire at the pulling hook of the equipment, and the hydraulic system will control the grappling hook to fix the tire, and then start the pulling device to strongly pull the steel wire in the bead directly out of the tire. The whole set of operations is safe and efficient, and can be adjusted according to different sizes of tyres.

OTR Tire Wire Drawing Machine Working Video

This video shows the OTR tire wire drawing machine in action, efficiently removing steel wires from large off-the-road tires.

Parameters of OTR Tire Debeader Machine

Below are the technical specifications of our OTR tire debeader machine, designed for efficient bead wire removal from large OTR tires.

| Power | 22+3kw |

| Length of machine | 4 metres |

| Weight | 9500kg |

| Handling of tire size | 1800-4000mm |

| Production capacity | 2 minutes/pc |

The OTR Tire Wire Drawing Machine Applications

The OTR debeader is widely used in:

- Mining tire recycling plants

- Giant tire processing centers

- Industrial waste management plants

- Scrap tire preprocessing lines

- OTR tire cutting & shredding systems

It is suitable for loader tires, grader tires, dump truck tires, crane tires, and other large engineering tires.

OTR Debeader in a Complete Tire Recycling Line

The OTR tire debeader is the first step of an OTR tire recycling system. A typical workflow includes:

OTR Debeader

Removes the high-strength steel beads from both sides of the OTR tire, making the tire easier to cut and shred while protecting the machines that follow.

Tire Cutter Machine

Cuts the bead-removed OTR tire into several sections, allowing smoother feeding and handling in later stages.

Tire Shredder

The cut tire sections are fed into the shredder, where they are further shredded into smaller rubber pieces to improve processing efficiency.

Rubber Powder Mill

Grinds the shredded rubber into fine powder, which can be used for recycled rubber, rubber products manufacturing, or other deep-processing applications.

OTR Debeader Price – How to Get a Quote

The price of an OTR debeader depends on:

- Tire size range

- Hydraulic pulling force

- Machine weight & reinforcement level

- Special customization

o receive an accurate quotation, simply send us:

- Your tire size range

- Daily/Hourly capacity requirement

- Any customization needs

Our team will provide a tailored solution and complete cost breakdown.

FAQ of The Tyre Debeader

1. What Tire Sizes Can Your OTR Debeader Handle?

From 25 to 63 inches, and custom options are available.

2. Can It Remove Beads From Both Sides?

Yes, both sides can be processed by repositioning the tire.

3. How Many Tires Can It Process Per Hour?

Typically 20–40 tires per hour, depending on tire size.

4. Do You Provide Installation And Training?

Yes — overseas installation, online guide, and training videos.