Fully Automatic Rubber Powder Production Line

The fully automatic rubber powder production line efficiently processes waste tires (≤1200mm) into rubber powder or granules through a fully automated system, from shredding to final collection, minimizing labor and ensuring consistent output.

What Types of Tires Can This Fully Automatic Rubber Powder Production Line Process?

During project discussions, one of the first questions we usually confirm with customers is the tire size range. This fully automatic rubber powder production line is designed to process waste tires with a diameter of 1200 mm or below, which covers the majority of recyclable tires available on the market and helps ensure stable and efficient operation of the entire line.

- Passenger Car Tires

- Light and Medium Truck Tires

- Standard-Size Engineering Tires (Small Industrial Tires)

- Waste Tires with Relatively Consistent Size and Structure

In real projects, we usually ask customers to share details such as tire diameter range, main tire types, and expected processing capacity, so we can confirm whether standard configurations are sufficient or if minor adjustments are needed.

If your waste tires are within 1200 mm in diameter but vary in structure, we can still evaluate your material conditions and recommend a more suitable fully automatic rubber powder production line configuration based on practical production needs.

Quality Performance of the Finished Rubber Powder

Before making a purchasing decision, many customers pay close attention to the quality indicators of the finished rubber powder. In our discussions, we usually focus on the following key aspects:

Rubber Powder Purity:

With a multi-stage steel and fiber separation design, the finished rubber powder can reach a purity of up to 99%, making it suitable for applications such as recycled rubber and various rubber products.

Particle Size Consistency:

The screening system ensures uniform particle size distribution, effectively reducing the proportion of oversized or excessively fine particles.

Wide Application Range:

Rubber powder of different mesh sizes can be produced according to specific requirements and is widely used in running tracks, rubber mats, modified asphalt, and related applications.

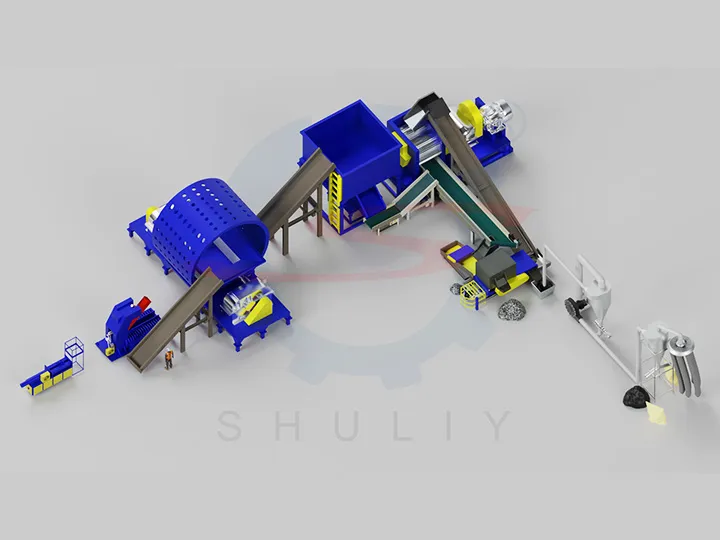

Available Configurations of Rubber Powder Production Line

To meet different production needs and factory layouts, the line is available in three configurations:

Standard Full Line with Separate Wire Drawing and Cutting

- Tire Bead Wire Drawing Machine: Pulling the rim out of the tyre.

- Tire Cutting Machine: Cut the tyre into three small sections.

- Tire Shredder: Shred the tyres into 3-5cm pieces.

- Rubber Crusher: Grinding of rubber blocks into powder or granules, a step that includes crushing, sieving, and magnetic separation.

- Nylon Fiber Separation System: Removes nylon fibers.

- Collection & Conveyor System: Rubber powder collection.

This configuration provides complete front-end separation and is ideal for users requiring maximum control over input material size and wire removal.

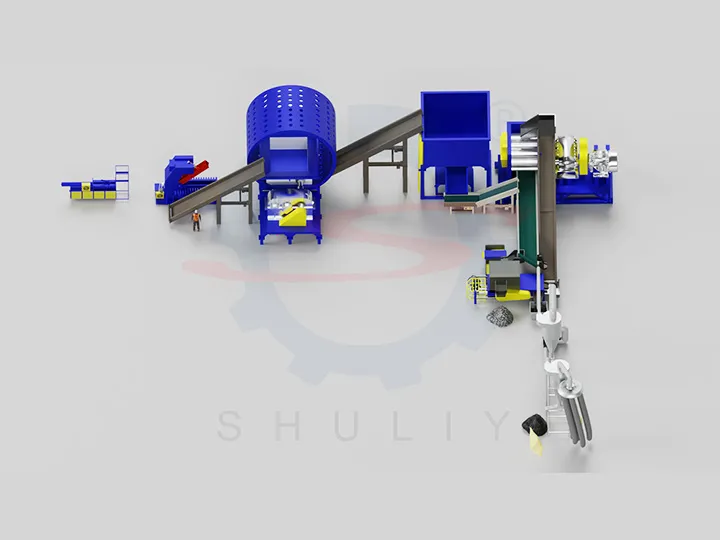

Diverse Pretreatment Configurations

- Tire Steel Wire Separator and Cutting Machine: Remove the part of the tire containing the rim on both sides while cutting off the other part of the tire.

- Tire Bead Wire Remover Machine: Separates steel wire from rubber.

- Industrial Tire Shredder: Breaks tires into smaller blocks.

- Rubber Crusher Machine: Final grinding and powdering.

- Nylon Separator: Nylon fiber removal.

- Collection Conveyor: Rubber powder collection.

Simplified Configuration for Pre-treated Tires

- Tire Recycling Shredder: Shred the tyres into small pieces.

- Rubber Crusher Machine: Produces rubber powder.

- Fiber Separator: Removes non-metal fiber.

- Collection Conveyor: Transports and collects the end product.

This simplified setup is suitable for operations that already receive pre-cut or bead-removed tires, focusing more on shredding and powder processing.

Features of the Rubber Powder Production Line

- Fully Automated Workflow: From shredding to powder collection, reducing manual handling and improving safety.

- Flexible Output Size: Adjustable rubber granule or powder size to meet various downstream applications.

- High-Purity Output: Dual magnetic separation and fiber removal systems ensure over 99% purity.

- Customizable Design: Each layout can be tailored to your plant size and production goals.

Whether you’re upgrading an existing line or setting up a new tire recycling facility, the fully automatic rubber powder production line offers a scalable and efficient solution for high-value rubber powder production.

This video showcases the working process of our fully automatic rubber powder production line. From waste tire shredding to fine rubber powder collection, the entire process is fully automated, minimizing manual labor and ensuring high efficiency.

Which Customers Is This Production Line Suitable For?

Based on our project experience, this fully automatic rubber powder production line is particularly suitable for the following types of customers:

- Companies planning to enter or expand the waste tire recycling and rubber powder processing business

- Recycled rubber processors with clear requirements for rubber powder quality and stable supply

- Rubber product manufacturers, such as rubber floor tiles, rubber mats, and related products, who require consistent raw material quality

- Investors looking to reduce long-term labor and management costs through automated equipment

If you are currently using semi-automatic or standalone machines, we can also help you gradually upgrade your existing setup to a more efficient fully automatic rubber powder production solution based on your current production conditions.

Canadian Customer Case: From Waste Tire Rubber Powder to Rubber Floor Tiles

https://www.shuliytire.com/rubber-powder-making-machine-sent-to-canada/We provided our Canadian customer with a complete solution: processing waste tires into rubber powder, which is then directly used for rubber floor tile production. The project included rubber powder production equipment, molds customized to the tile specifications, and rubber floor tile forming machines.

With this integrated setup, the customer efficiently utilizes waste tire resources, creating a seamless process from raw rubber powder to finished floor tiles. We also collaborated closely with the customer to confirm rubber powder specifications and production processes, ensuring smooth implementation of tile manufacturing.

We Provide More Than Just Equipment

In actual cooperation, we do not only supply the fully automatic rubber powder production line itself. We also work closely with customers to:

- Analyze raw material types and target markets

- Plan reasonable production capacity and equipment configuration

- Provide installation guidance, commissioning support, and ongoing technical communication

If you are exploring a fully automatic rubber powder production line, or would like a tire recycling and rubber powder production solution better suited to your project, we welcome you to reach out to us.