Tire Debeader

The tire debeader is a pre-processing machine used to completely pull out the steel beads from used tyres, effectively improving the purity of the rubber powder and reducing the wear and tear of the subsequent equipment. We offer both single-hook and double-hook models, which customers can choose according to production capacity and demand.

What Is a Tire Debeader Machine?

The waste tire steel wire removal machine is a specially designed machine used to remove the steel bead wires from waste tires before shredding or grinding. It is suitable for tires with a diameter of less than 1200mm and serves as an essential pre-treatment step in the rubber powder production line.

By extracting the bead wires in advance, the machine helps produce cleaner rubber granules or powder while reducing wear and tear on the tire shredder machine, ultimately extending the service life of downstream equipment and lowering maintenance costs.

This video shows how a single-hook wire drawing machine and a double-hook wire drawing machine can efficiently pull steel wire loops out of waste tyres from the sidewalls of the tyres, preparing them for subsequent crushing.

Are You Facing the Following Challenges?

- Low efficiency in bead wire separation: Traditional manual methods or simple equipment are slow, severely impacting overall production capacity.

- High labor costs: Separating bead wire requires significant manpower, leading to persistently high operating costs.

- Safety hazards: Traditional working methods pose risks of cuts and crushing, increasing the likelihood of occupational accidents.

- Low bead wire recovery value: Incomplete separation leads to reduced recovery rates and purity of the steel wire, affecting its secondary sales value.

- Difficult equipment maintenance: Existing equipment is prone to wear and tear, with high maintenance costs that disrupt continuous production.

Shuliy Tire Debeader: Your Ideal Choice!

We understand your pain points. The Shuliy tire debeader integrates multiple innovative technologies, designed to provide you with the most outstanding solution.

Core Advantages and Technical Highlights:

- Efficient Hydraulic System: Core components utilize a high-quality motor-driven hydraulic system, providing a continuous and powerful source of energy.

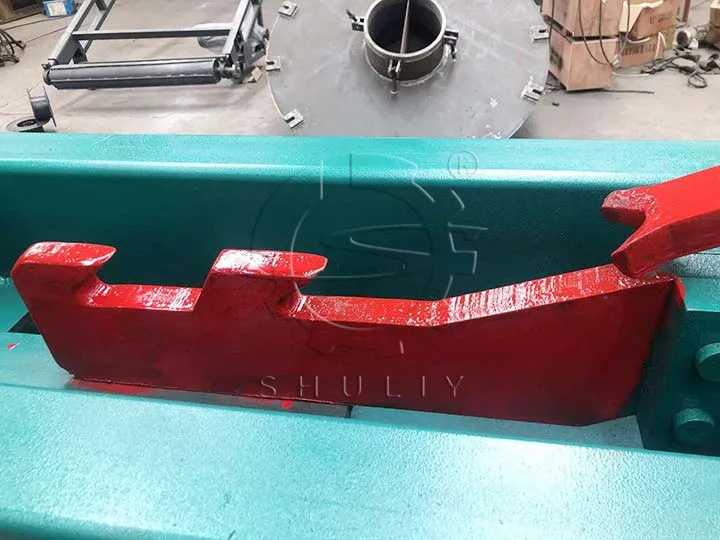

- Precise Traction Design: Specially designed traction hooks accurately grip the bead wire inside the tire, ensuring stable and reliable traction with every pull.

- Complete Wire Extraction: Leveraging powerful hydraulic force, the machine thoroughly and efficiently extracts the bead wire, maximizing its integrity and preventing breakage. This lays the foundation for high-value recycling.

- Targeted Design: Specifically optimized for tires with a diameter less than 1200 mm, ensuring optimal adaptability and processing results.

- Diverse Model Options: From the economical single-hook model to the efficient double-hook and the ultimate double-sided double-hook designs, you can choose the most suitable model based on your production volume needs and budget.

- Increased Production Capacity: The double-hook and double-sided double-hook models significantly shorten the processing time per tire, greatly enhancing overall production efficiency.

Tailored for Diverse Needs: The Shuliy Tire Debeader Series

We understands that tire recycling enterprises of all scales have unique production requirements and budget considerations. Therefore, we have meticulously developed three tire wire drawing machine models specifically designed for tires with a diameter less than 1200 mm, aiming to provide you with the most practical and efficient bead wire separation solutions.

- Single-Hook tire debeader: Equipped with a single powerful traction hook, driven by the hydraulic system, it accurately grips the bead wire ring from one side of the tire and efficiently and completely extracts it.

- Double-Hook debeader machine: Features two synchronously operating traction hooks. In a single reciprocating motion, these two hooks can simultaneously grasp and pull out the bead wire rings from both sides of the tire, from the same side of the tire.

- Double-Hook and double-sided tire debeader: Possesses two independently yet synchronously operating traction hook systems, capable of working from both sides of the tire simultaneously. This means that in one complete cycle, it can extract the bead wire rings from both sides of the tire, from each respective side of the tire.

Working Principleof The Tire Debeader

The machine consists of a frame, motor, hydraulic system, drawing hook, and drawing mouth. During operation, the motor powers the hydraulic system, driving the pulling hook to perform a reciprocating motion.

Once the tire is positioned on the drawing mouth, the hook grasps the internal bead wire of the tire. With strong hydraulic force, the machine extracts the steel wire completely and efficiently, ensuring the wires remain intact and ready for further recycling.

Parameters of The Tire Block Cutter

The following parameters of the tire debeader are for your reference. If you need to get a quotation or customised service, please feel free to contact us for more information.

| Model | Single Hook Tyre Debeader | Double Hook Tire Drawing Machine | Double-Hook and double-sided tire debeader |

| Power | 11kw | 18.5kw | 22kw |

| Machine Size | 4.1*0.7*1.7m | 4.2*0.9*1.7m | 2270*1660*1520mm |

| Weight | 1400kg | 1500kg | 6.5t |

| Handling Tyre Size | 900-1200mm | 900-1200mm | 900-1200mm |

| Production Capacity | 20-30pcs/h | 40-50pcs/h | 60-120pcs/h |

How to Assemble a Complete Rubber Powder Production Line

A complete rubber powder production line can transform waste tires into high-value rubber materials, achieving resource recycling. Shuliy provides key equipment and plans the optimal production line configuration for you.

- Tire Debeader Machine: To remove the bead wire rings from the tire. This is the first step in subsequent processing, ensuring effective separation of the steel wire for recycling.

- Tire Cutter: To cut the whole tire into 2-3 sections. This step is to reduce the tire’s size, making it easier to feed into the shredder for further processing.

- Tire Shredder Machine: To shred the cut tire sections into smaller pieces. The shredder is the key equipment for significantly reducing tire size, preparing it for subsequent grinding into powder.

- Rubber Cracker Mill: To grind the shredded small rubber pieces into the desired rubber powder or granules. This is the final product stage of the production line, with fineness adjustable based on market demand.

Tire Recycling Machine For Sale

Shuliyis committed to providing you with one-stop waste tire processing solutions, offering professional support from equipment selection to production line planning. Should you be interested in tyre debeaders or complete rubber powder production lines, you may contact us via the form on our website or directly through WhatsApp. We shall provide you with further details and a quotation.