Tire Shredding Machine

Tire shredding machine is a core machine in tire recycling lines, used to shred steel-free or pre-cut tyres into 50–100mm rubber blocks for further grinding and steel separation. It helps produce cleaner rubber granules or powder, widely used in recycled rubber, mats, and runways.

Main Functions & Applications

The core function of a scrap tire shredder is to effectively shred large, high-strength waste tyres into rubber blocks of controlled size for subsequent processing. It is suitable for small car tyres, truck tyres, and OTR tyres after removing the steel rim.

The video shows the tire shredding machine in action, efficiently shredding waste tires into uniform rubber blocks for further recycling.

Advantages of The Scrap Tire Shredder

- Wide Application: Suitable for various sizes of tires, including small tires and large OTR tires.

- High Efficiency: Single machine capacity ranges from 2 tons/hour to 20 tons/hour.

- Customizable Screen: Screen mesh can be customized to control output size.

- Robust Structure: Blades are made of high-strength alloy steel; the frame is sturdy and built to last.

Structure and Working Principle of Tire Shredding Machine

The tyre shredder consists of the following main parts:

- Feeding Hopper: Used to load tire materials.

- Motor and Transmission System: Provide stable power for shredding.

- Shredding Chamber and Blades: Responsible for tearing and cutting the tires.

- Circular Screen: Screens rubber blocks that meet the required size.

- Heavy-Duty Frame: Ensures the machine runs smoothly and is durable.

Tire Shredding Machine Working Process: Tires are conveyed into the feeding hopper. Once the motor is started, the transmission system drives the blade shafts to rotate at high speed, shredding the tires into smaller pieces.

Rubber blocks that meet the required size are discharged through the circular screen and move to the next processing step. Oversized pieces remain in the shredding chamber for further processing until they meet the desired size. The aperture of the circular screen can be customized according to customer requirements to achieve different output sizes.

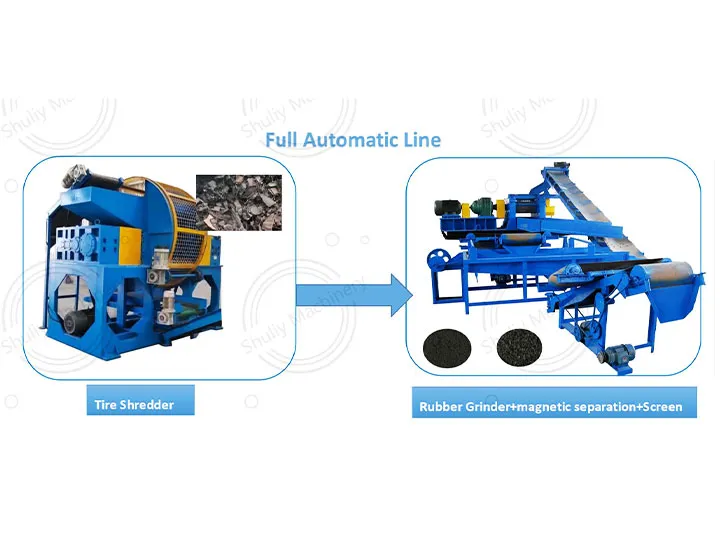

Integrated Rubber Powder Production Line

Is your ultimate goal to transform waste tires into high-value rubber powder or granules? Our tire shredding machine is the core unit for building an efficient production line. It can be seamlessly integrated with a range of pre-treatment and further processing equipment to form a complete, automated rubber powder production line:

Pre-treatment Stage: First, tyres are dismantled using equipment such as tire debeaders, cutting machines, and steel wire separators to remove steel wires and tyre beads, preparing them for efficient shredding.

Core Shredding Stage: The processed tire blocks are fed into our tire shredding machine and are crushed into uniform small pieces, which is the ideal feedstock for subsequent grinding.

Fine Grinding Stage: The shredded rubber chips are conveyed to a rubber powder mill and pulverized into rubber powder of various fineness levels , ready for market sale or further processing.

Several Different Production Solutions for Rubber Powder

Parameters of The Rubber Tire Shredder Machine

Our tire shredding machines are available in multiple models to meet various processing capacities, ranging from 2 tons to 20 tons per hour. The machines are designed for high-efficiency shredding of car tires, truck tires, and dismantled OTR tires. The specifications below include key performance indicators such as power, capacity, output size, and blade configuration, helping you choose the most suitable model for your recycling needs.

| Model | 900 | 1000 | 1200 | 1500 | 1800 |

| Power | 64.5kw | 94.5kw | 157kw | 188.5kw | 328.5kw |

| Capacity | 2 t/h | 4 t/h | 5-6 t/h | 8-10 t/h | 15-20 t/h |

| Main unit size | 4*2.2*2.8m | 5*2.6*3.2m | 5*2.6*3.2m | 20*10*3.5m | 20*12*4m |

| Footprint size | 9*5*2.8m | 10*6*3.2 m | 10*6*3.2 m | 20*10*3.5 m | 20*12*4 m |

| Feed size | <900mm | <1000mm | <1200mm | <1200mm | <1400mm |

| Output size | 50mm | 60mm | 60mm | 75mm | 100mm |

| Knife diameter | 360mm | 440mm | 510mm | 580mm | 650mm |

| Number of blades | 16 | 16 | 18 | 20 | 18 |

How to Choose the Right Tyre Shredder Model?

Choosing the right tire shredder is the first step to a successful investment. Please consider the following factors:

Material to Be Processed

Do you primarily process car tires, truck tires, or giant OTR tires? Different models have different processing capacities and power requirements.

Target Output Capacity

What is your target hourly or daily output? We can customize higher-capacity tire shredding machine models based on your needs.

Output Size

What is your desired output size? 50x50mm rubber chips, or finer granules? Different output requirements affect equipment configuration and downstream processes.

Investment Budget

A clear budget helps us recommend the most cost-effective solution within your range, balancing upfront investment with long-term operating costs

Why Choose Shuliy Machinery?

- Over ten years of experience in waste tyre recycling equipment, delivering reliable, high-performance machines.

- Customisable solutions: tire shredding machine screens, blades, output size, layout can all be tailored to your site.

- Full after-sales service: on-site installation/commissioning, operator training, one-year warranty, lifetime technical support.

- Global export footprint: clients in Europe, Africa, North America, Southeast Asia, many successful case studies.

Get Your Customized Solution Now

Contact us today with your specific requirements (e.g., types of tires to process, target output, budget). Our experts will provide you with a free initial proposal and quotation。

Your Next Step:

Email your requirements to: info@shuliytire.com

Or use our website’s live chat for instant inquiry