Semi-automatic Waste Tire Recycling Plant

The semi-automatic waste tire recycling plant is a practical and cost-effective solution for processing used tires into rubber powder or granules. Designed for tires with a diameter of less than 1200mm, this line combines manual and automated processes to achieve efficient tire recycling with high output quality.

Understanding Customer Needs from a Supplier’s Perspective

In our discussions with customers planning tire recycling projects, several key concerns are raised repeatedly:

- Whether the raw materials are easy to process and the production flow is clear

- Whether the purity of the finished rubber powder meets downstream requirements

- Whether the rubber granule and powder size can be adjusted

- Whether the investment level and operating complexity match the current stage of the project

Based on these practical considerations, we have developed this semi-automatic rubber powder production line, aiming to balance product quality, operational flexibility, and cost control.

Raw Materials and Application Range

- Raw material: Waste automobile tires

- Applicable tire diameter: ≤ 1200 mm

- Application scenarios: Small and medium tire recycling plants, recycled rubber processors

This waste tire recycling plant configuration ensures sufficient processing capacity while avoiding unnecessary equipment redundancy, making it suitable for steadily developing operations.

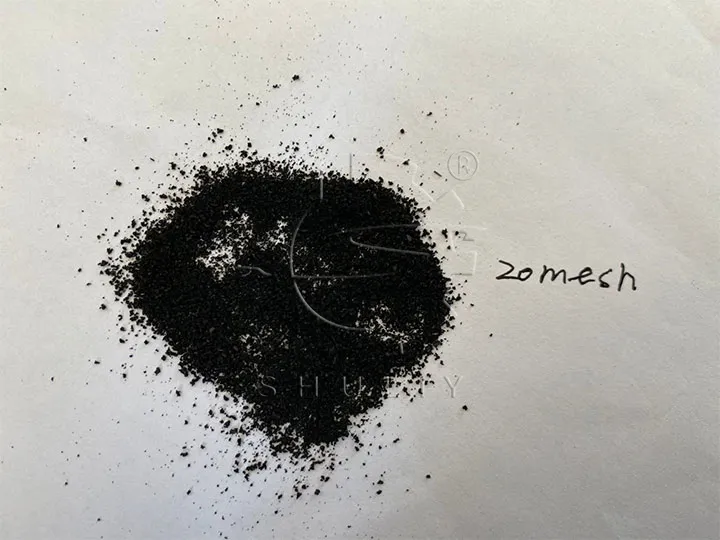

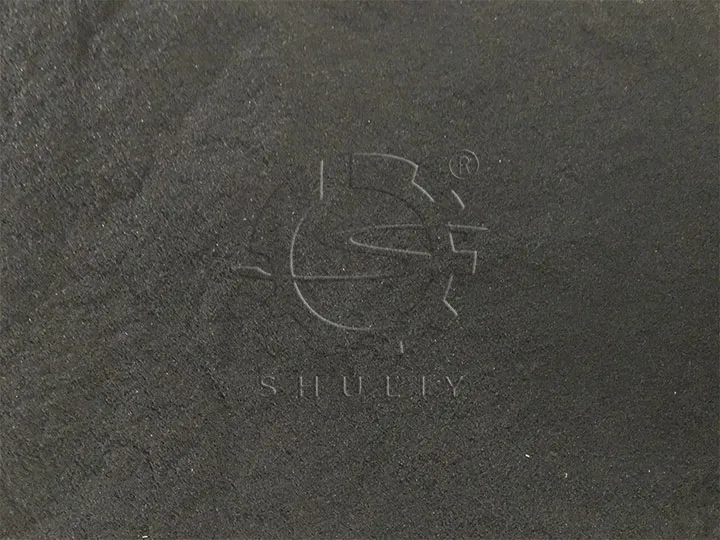

Finished Rubber Powder and Granule Characteristics

Under proper operation and maintenance conditions, this semi-automatic rubber powder production line can achieve:

- Rubber powder purity: Over 99%

- Granule / powder size: Adjustable to meet different application requirements

- Impurity control: Effective separation of steel wire and non-rubber components

The finished products can be used in rubber products, rubber flooring, reclaimed rubber, modified materials, and other related industries.

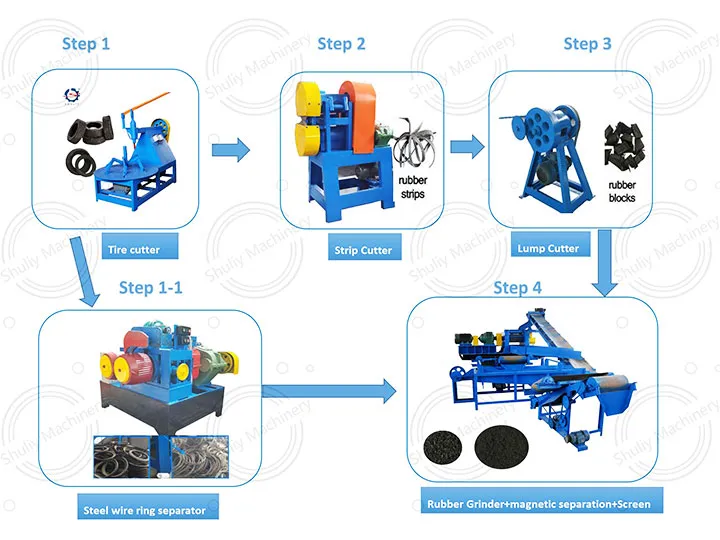

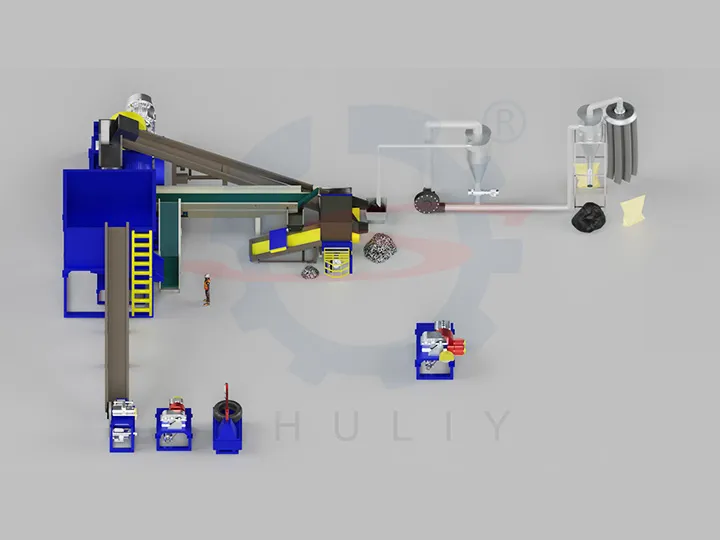

Equipment Included and Working Process

This waste tire recycling plant consists of the following main machines:

- Tyre sidewall cutter: Cut off the sidewall of the tyre containing the rim.

- Waste tire strip cutter: Cut the tyre with the rim removed into strips.

- Tyre block cutting machine: Cut the rubber strips into 3-5cm pieces.

- Tire steel wire separator: Effective separation of the rubber from the rim of the tyre section cut by the sidewall cutter.

- Rubber Crusher: The automated chain consists of crushing, screening, and magnetic separation units that efficiently process tire blocks into high-purity rubber powder with the right particle size and fewer impurities.

- Fiber separator: Separation of fine fibres in the rubber powder to achieve 99% purity.

Operational Video of the Waste Tire Recycling Plant

This video provides a comprehensive overview of the entire working process of the semi-automatic tire recycling line. The first half of the process involves manual pre-treatment steps, including bead cutting, strip cutting, block cutting, and steel separation. These steps typically require 2 to 3 workers to manually operate and ensure that the tires are properly dismantled into sizes suitable for further crushing.

The latter half is handled by automated equipment, which performs crushing, screening, and magnetic separation, ultimately producing high-purity rubber powder or granules.

Features of the Semi-automatic Waste Tire Recycling Plant

- High Cost-Performance Ratio: The equipment requires relatively low investment, making it ideal for small to medium-sized recycling plants to start production.

- Adjustable Output Size: The size of rubber powder or granules can be flexibly adjusted according to customer requirements, suitable for various application scenarios.

- High Purity Output: Equipped with dual magnetic separators and a nylon fiber separator, the final rubber powder can reach over 99% purity with stable quality.

- Customizable Design: The system can be customized based on the customer’s plant layout, capacity needs, and product specifications.

FAQs of the Semi-automatic Waste Tire Recycling Plant

Why Many Customers Choose This Configuration

From our project experience, many customers focus on controllable investment, reliable operation, and consistent product quality at the initial stage. This semi-automatic rubber powder production line achieves a practical balance by:

- Avoiding overly complex structures and focusing on real production results

- Keeping maintenance and replacement costs relatively manageable

- Allowing future upgrades toward higher levels of automation

From Equipment Supply to Long-Term Partnership

For us, supplying a semi-automatic rubber powder production line is not just about delivering equipment, but about helping customers successfully enter the tire recycling and rubber powder processing industry.

If you are evaluating a rubber powder production solution for tires with a diameter below 1200 mm, or would like to compare different capacities, configurations, and upgrade options, we are ready to provide recommendations based on your actual needs.

Feel free to contact us to learn more about the technical details and application possibilities of this semi-automatic waste tire recycling plant.