OTR Waste Tire Recycling Line

The OTR Waste Tire Recycling Line is specially designed to process oversized industrial and mining tires, which are typically difficult to handle due to their large size and high steel content. This recycling system offers two tailored solutions based on the tire diameter, ensuring efficient size reduction and high-purity rubber powder output.

Types of Tires Suitable for This OTR Recycling Line

This OTR rubber powder production line is suitable for processing:

- Construction machinery tires

- Mining dump truck tires

- Loader and bulldozer tires

- Large agricultural machinery tires

- Other industrial tires with large diameters and high steel content

Different pre-treatment solutions can be selected based on tire size and structure to improve processing efficiency and reduce equipment wear.

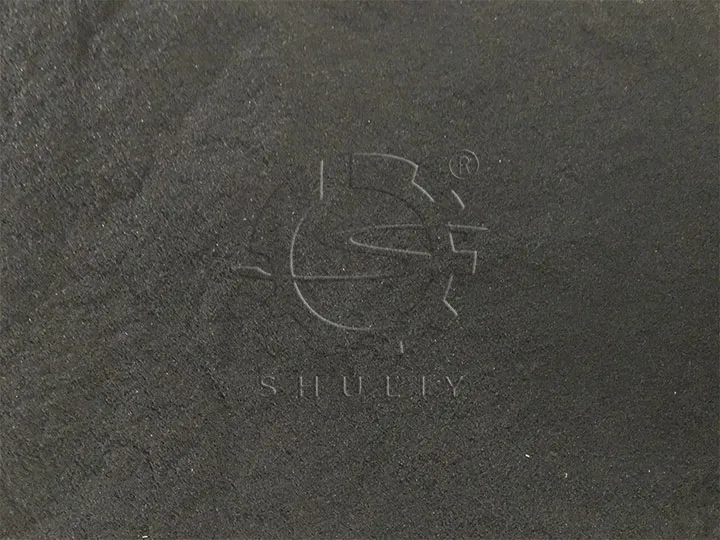

Final Products and Particle Size Options

After processing through the OTR tire recycling line, the following products can be obtained:

- Rubber chips

- Rubber granules

- Rubber powder

Common particle size ranges include:

- 5–10 mm

- 1–5 mm

- 20–40 mesh and finer rubber powder

Magnetic separation and fiber removal systems can be integrated to reduce steel and fiber content, ensuring high-purity rubber powder.

Applications of Recycled Rubber Products

Rubber granules and rubber powder produced by the OTR recycling line are widely used in:

- Rubber floor tiles and mats

- Sports surfaces and artificial turf infill

- Modified asphalt

- Reclaimed rubber products

- Anti-vibration pads and sound insulation materials

- Industrial rubber product manufacturing

Further downstream processing can significantly increase the added value of recycled OTR tires. Our company provides relevant rubber tile making machines, and if you need them, we can also provide you with the details of the machine.

Features of The OTR Waste Tire Recycling Line

- Designed for Extra-Large Tires: Specially built to process oversized OTR tires with diameters ranging from 1800mm to 4000mm, such as mining and construction tires.

- Heavy-Duty Equipment Configuration: Large-scale drawing machines, disintegrators, shredders, etc., specially designed for the treatment of OTR tyres.

- Customized Processing Options: Two processing schemes are available to suit various tire sizes, structures, and materials, offering flexible solutions tailored to customer requirements.

Two Solutions of OTR Tire Recycling Line

For the OTR waste tire recycling line, we offer two solutions that you can refer to. Of course, we can also provide customised solutions according to the specific needs of our customers.

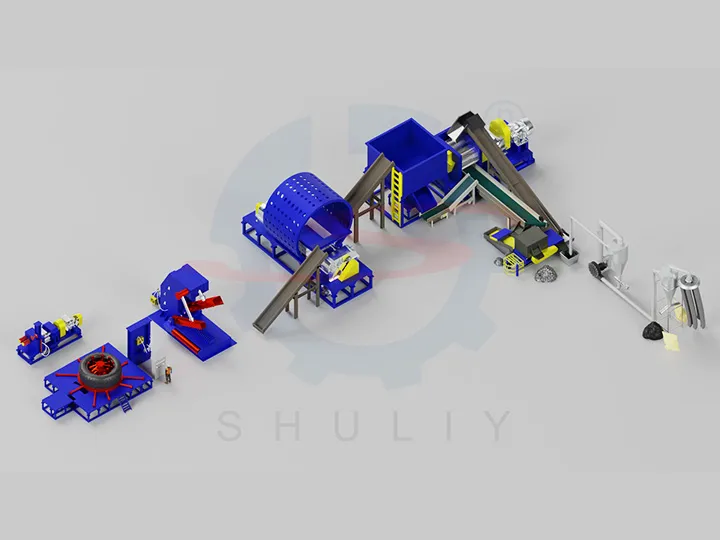

Solution 1: Wire Drawing + Cutting + Shredding + Grinding

This solution is ideal for large OTR tires used in heavy-duty machinery. It includes the following equipment:

- OTR Tire Debeader Machine – Extracts the thick steel wire from tire beads.

- OTR Cutter – Cuts large tires into manageable sections.

- Tire Shredder (Model 1200 or above) – Shreds tire blocks into smaller rubber chips.

- Rubber Crusher (Model 450 or above) – Grinds chips into fine rubber powder.

- Nylon Fiber Separator – Removes nylon fibers from rubber.

- Rubber Powder Collection & Conveyor System – Collects and transfers finished rubber powder.

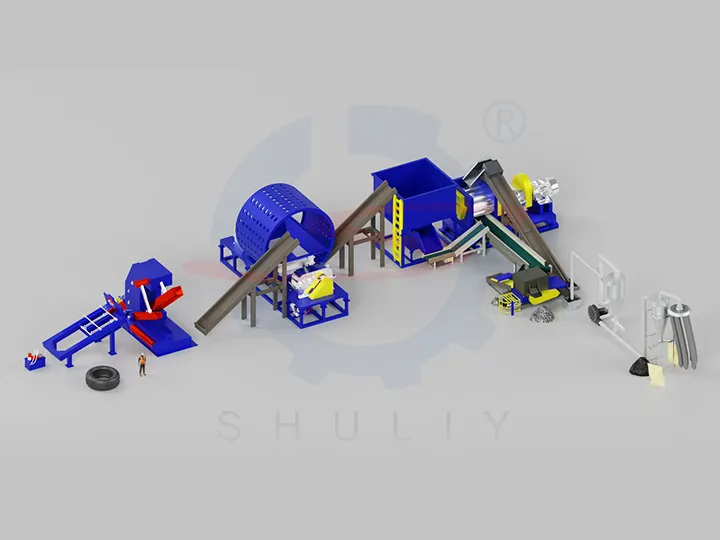

Solution 2: Tire Dismantling + Steel Separation + Shredding + Grinding

The pre-treatment stages are different and can be selected by the customer according to specific needs.

- OTR Dismantling Machine – Cuts the tire ring and separates the sidewall from the tread.

- OTR Cutter – Further reduces tire size.

- OTR Steel Wire Separator – Effectively removes embedded steel components.

- Tire Shredder Machine(Model 1200 or above)

- Rubber Grinder (Model 450 or above)

- Nylon Fiber Separator

- Rubber Powder Collection & Conveyor System

Frequently Asked Questions (FAQ) of The Waste Tire Recycling Line

What Is the Difference Between an OTR Tire Recycling Line And a Passenger Car Tire Recycling Line?

A: OTR tires are much larger and contain significantly more steel. They require stronger pre-treatment equipment and heavy-duty shredding and grinding systems, which standard tire recycling lines cannot handle directly.

Can I Purchase Only Part of the Equipment?

A: Yes. Customers can purchase individual machines such as wire drawing machines, tire shredders, or rubber grinding machines according to their existing setup.

What Rubber Powder Purity Can Be Achieved?

A: With proper magnetic separation and fiber removal systems, rubber powder purity can reach over 99%, depending on the required particle size.

Can The Processing Capacity Be Customized?

A: Yes. We offer multiple equipment models suitable for small to large-scale OTR tire recycling projects.

Contact Us for Details on OTR Tire Recycling Equipment

The OTR waste tire recycling line provides an effective solution for processing large waste tires while converting them into valuable rubber products. With flexible configurations and proven processing technology, we deliver reliable OTR Rubber Powder Production Line solutions for different customer needs.

For detailed configurations, capacity options, or pricing information, please feel free to contact us.